The pace of industrial automation continues to pick up steam as companies add robots, digitize key workflows, and optimize equipment in pursuit of increased productivity, improved product quality, and greater resiliency.

Often, the ongoing enhancements and requisite updates are the domain of single engineer or specific PLC controls teams, which rely on a cocktail of institutional knowledge and vendor-specific programming environments to keep the automation landscape up-to-date on an ongoing basis.

However effective that workflow has been, the model is strained when the team expands beyond a core set of automation controls experts or if there is sufficient desire to scale the changes across different processes or even multiple plants. Think about how hard it is to get funding for robotics and automation equipment. As difficult as that process is, it’s often more of a challenge to assemble the resources and expertise needed to get industrial automation systems deployed and running smoothly.

Given the constraints, it can be difficult to scale industrial systems effectively without the risk of unexpected down time. Moreover, the specificity of traditional automation control tools and the lack of cross-platform PLC programming expertise greatly limits who can handle these responsibilities, which can bring modernization and upgrade efforts to a crawl.

Introducing Industrial DevOps

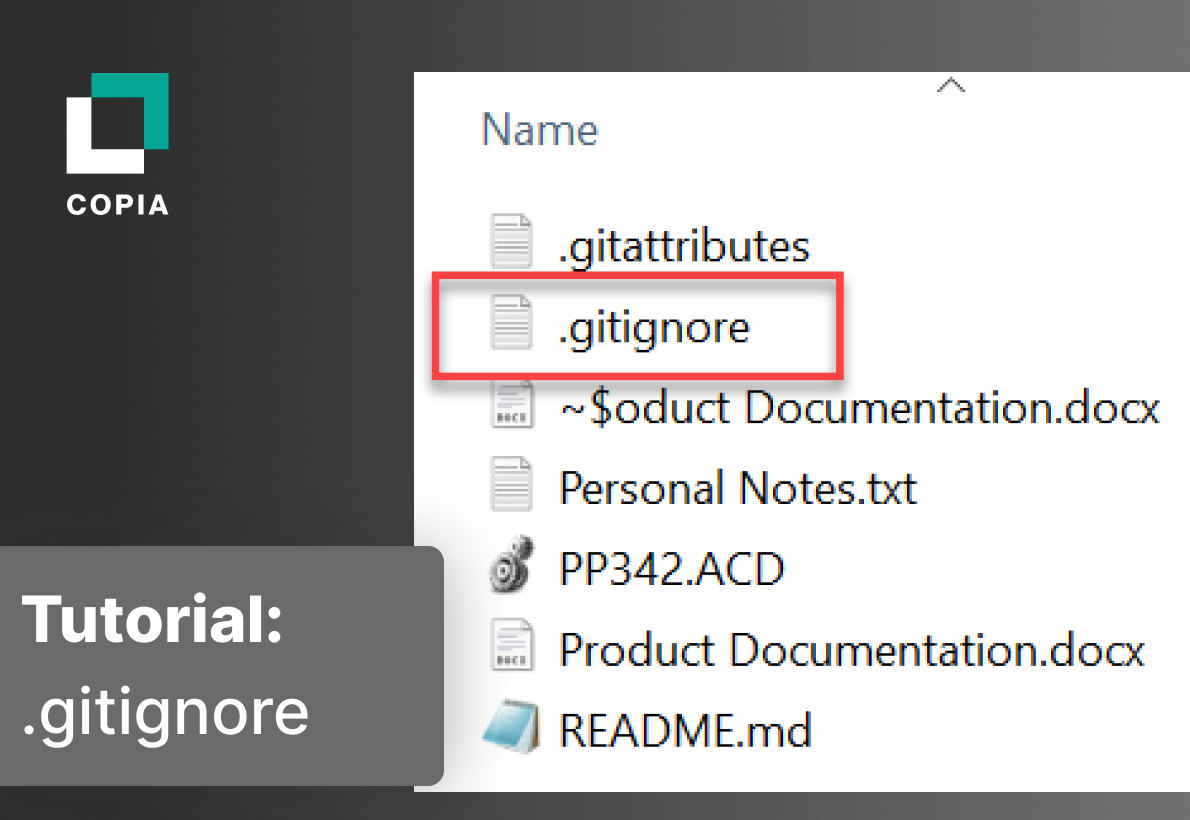

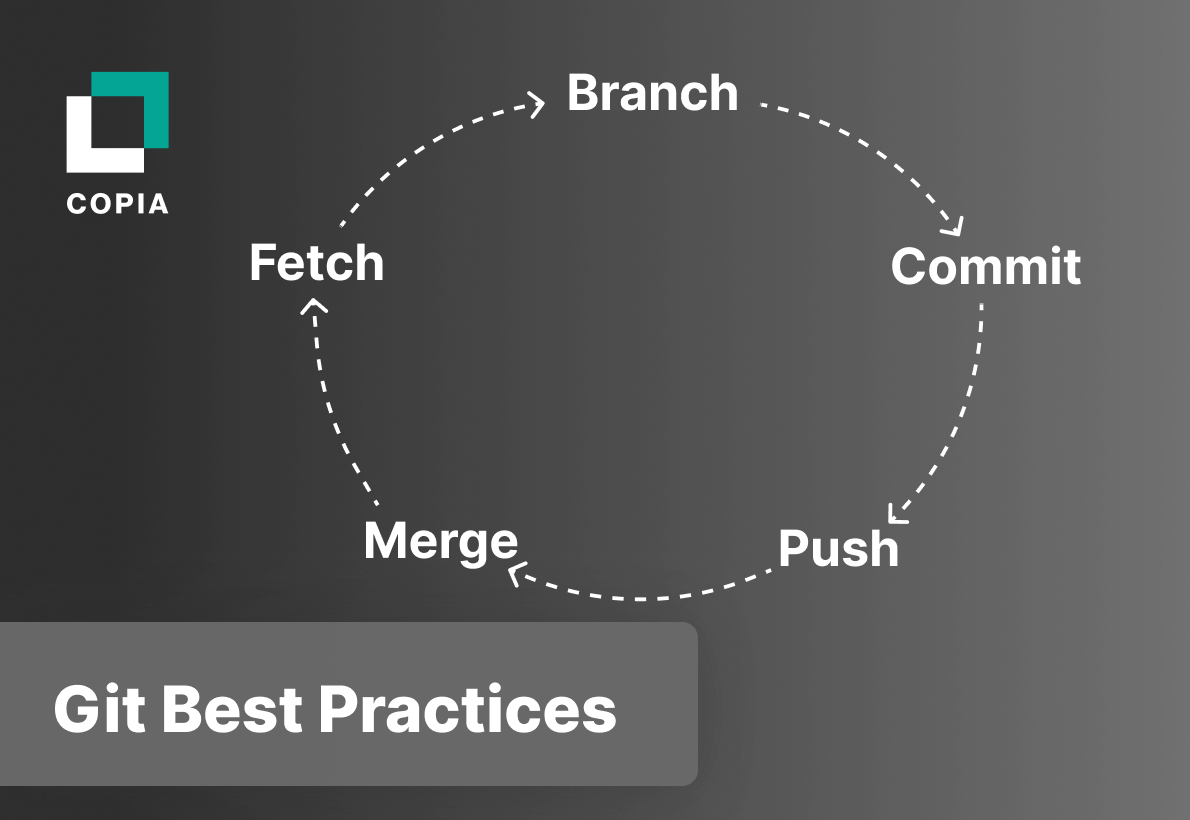

Enter a modern approach to PLC programming that embraces IT constructs such as Git-based source control and DevOps practices. Embracing an industrial DevOps approach can introduce a level of scalability for plant floor operations that is simply not possible with traditional PLC programming tools and workflows.

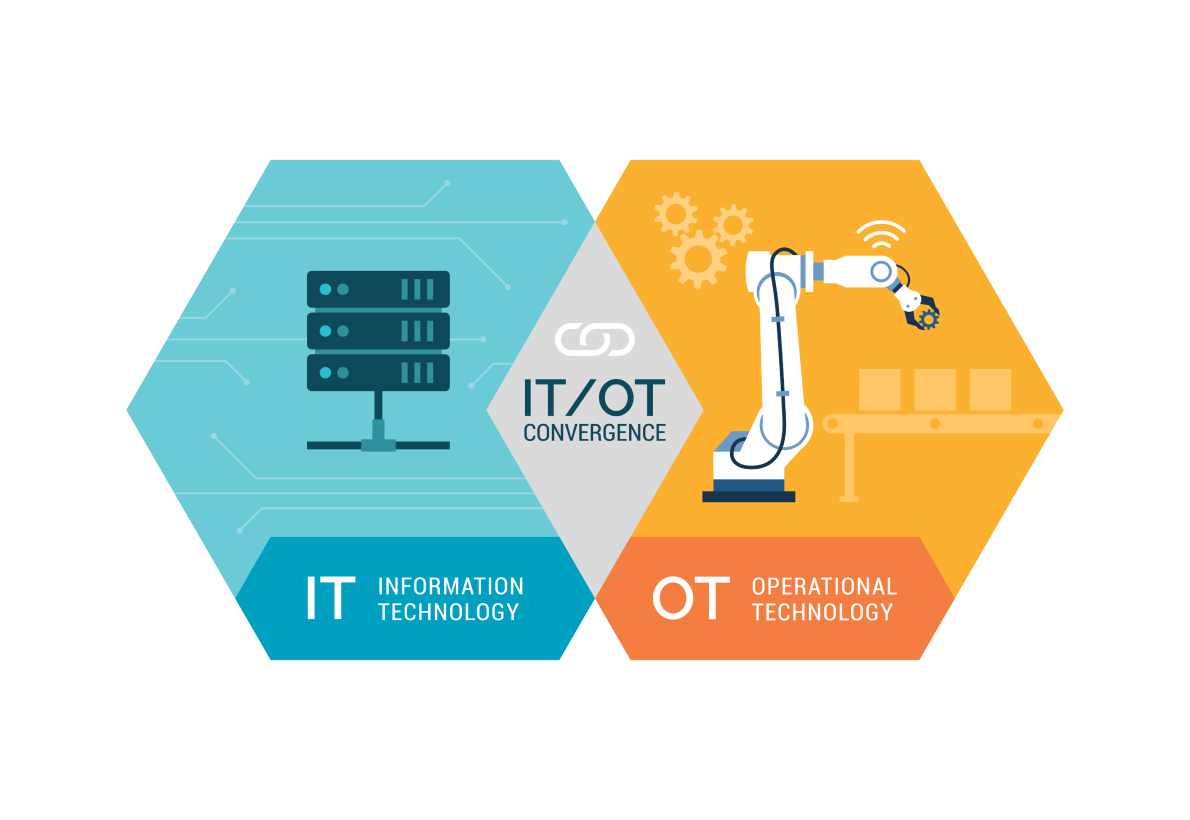

Standardizing on a modern PLC programming platform that takes a page from familiar IT software programming constructs bridges the gap between specialized OT expertise and mainstream software development skills. This enables companies to more easily scale automation efforts and expand the resources and manpower spearheading these critical industrial modernization projects.

Junior-level engineers, some of whom are already familiar with Git and DevOps practices and tools, can quickly come up to speed to support industrial automation efforts without formal knowledge of legacy or siloed PLC programming technologies. Senior-level engineers can spend less time training and reviewing junior engineers’ work. This enables them to easily offload routine changes and maintenance tasks, allowing senior staffers to focus on higher-value automation requirements.

PLC programming tools based on mainstream IT technologies and practices can also widen the net for attracting new industrial automation talent. There are larger numbers of job candidates versed in those tools than those familiar with conventional PLC and controls platforms. Younger engineers are also partial to working with a modern, IT-like toolset as opposed to legacy PLC controls platforms. Not only does an industrial DevOps environment feel familiar, the skill set is more universal and highly transferable for career advancement.

Using Git as the underlying, unifying infrastructure helps IT and OT find a common language and obtain visibility into all activity. It reduces the complexity of managing multiple OT toolchains and disparate systems, eliminating the “black box” in industrial automation.

Copia Automation’s Git-based source control platform fits the bill for bridging the IT/OT divide. The platform’s unique spin on enabling industrial DevOps practices accelerates scalability, ensuring organizations are not left behind. Interested in learning more about how Copia can help you scale your PLC programming?

Check out our on demand webinar on Applying DevOps Strategies to PLC Code Development.