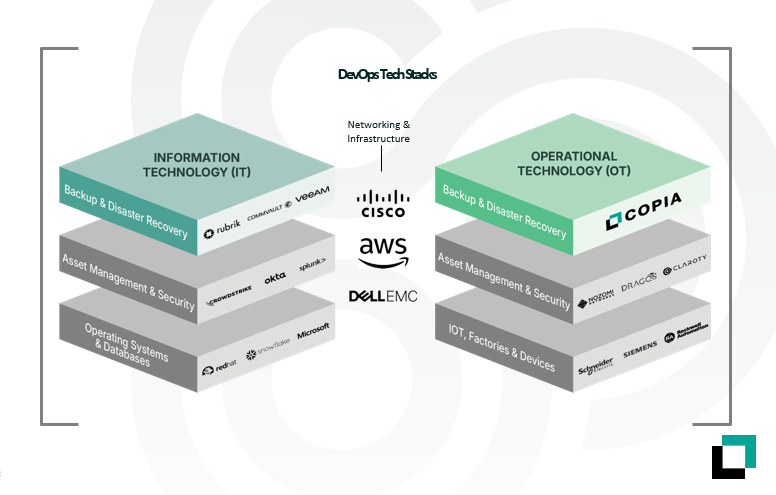

The Fourth Industrial Revolution, with its emphasis on connectivity and data sharing, has brought tremendous opportunities to the manufacturing sector. Increased efficiency, improved data analytics, and greater flexibility are just some of the benefits. But this interconnectedness also introduces significant vulnerabilities, particularly in the realm of cybersecurity. As manufacturers and distributors connect more devices and systems to their networks—from PLCs on the operations floor to enterprise-level IT systems—they become increasingly susceptible to cyberattacks. The State of Industrial DevOps Workforce Report underscores the growing cybersecurity concerns among industry experts and the critical importance of implementing robust security measures. Cybersecurity is no longer just an IT issue; it’s a fundamental business imperative. A successful cyberattack can disrupt operations, cripple production lines, damage a company’s reputation, and lead to substantial financial losses. Manufacturers and distributors must adopt a proactive, multi-layered approach to cybersecurity, recognizing that it’s not simply about protecting data; it’s about safeguarding their entire operation, their employees, and their future.

The report highlights the crucial need for integrating cybersecurity directly into industrial code and PLC programming software. This includes implementing secure coding practices from the outset, conducting regular vulnerability assessments to identify and address potential weaknesses, and providing comprehensive security training to all employees, from engineers and technicians to management and administrative staff. Manufacturers and distributors must also ensure that their systems comply with relevant cybersecurity standards and regulations, such as NIST’s Cybersecurity Framework or ISO 27001. Data integrity features, secure communication protocols, and robust access control mechanisms are all essential components of a comprehensive cybersecurity strategy. Strong password policies, multi-factor authentication, and regular security audits should be standard practice.

But technology alone is not enough. A strong cybersecurity posture requires more than just the latest software and hardware. Manufacturers and distributors must also cultivate a culture of cybersecurity awareness within their organizations. Employees at all levels need to understand the risks associated with cyberattacks and be trained on how to identify and respond to potential threats. This includes recognizing phishing scams, understanding the dangers of clicking on suspicious links, and following best practices for data handling. Regular security awareness training, coupled with clear communication about the company’s cybersecurity policies and procedures, is vital. Manufacturers and distributors should also establish incident response plans to prepare for and effectively manage any security breaches that may occur. This plan should outline clear roles and responsibilities, communication protocols, and procedures for containing the attack, recovering data, and minimizing downtime.

Cybersecurity should be a top priority for every manufacturer, regardless of size. It’s not just about protecting against external threats; it’s also about mitigating internal risks, such as accidental data breaches or malicious insider activity. By investing in robust cybersecurity measures and fostering a culture of security awareness, manufacturers and distributors can protect their valuable assets, maintain business continuity, and build trust with their customers and partners. In today’s interconnected world, cybersecurity is not just a cost of doing business; it’s a strategic investment in long-term success.

Stay tuned for the last installment of this 5-part series, The Power of Industrial DevOps: Driving Efficiency and Collaboration.