To understand the future of manufacturing, you have to look at its past. The principles that drove Henry Ford’s assembly line and W. Edwards Deming’s quality revolution in Japan didn’t just build cars—they created a philosophy of process. That same philosophy, focused on eliminating waste and building in quality, eventually jumped from the physical to the digital world, sparking the Agile and DevOps movements that define modern software.

Today, that journey comes full circle. We are now applying those mature, battle-tested software principles back to the factory floor. This is the essence of Industrial DevOps.

The Great IT/OT Divide

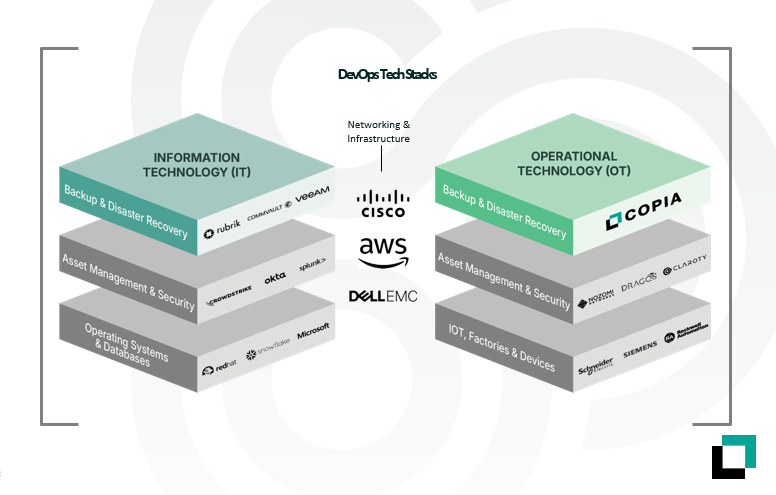

For decades, Information Technology (IT) and Operational Technology (OT) have spoken different languages. IT speaks of dynamic scalability, cloud infrastructure, and rapid deployment. OT speaks of unwavering reliability, physical safety, and the deterministic logic of PLCs. A request for ‘more agility’ from IT can sound like ‘more risk’ to OT.

This cultural and technical gap has been a major barrier to progress. But as connectivity and software-defined operations become the norm, bridging this divide is no longer optional. Industrial DevOps acts as the universal translator, creating a shared vocabulary and toolset to pursue the common goals of efficiency and security.

ICLM: The Foundation for a New Era

So how do you translate theory into practice? The technical foundation of Industrial DevOps is Industrial Code Lifecycle Management (ICLM).

ICLM is the systematic management of all industrial automation code as the critical asset it truly is. It moves operations from a world of manual backups, unknown code changes, and ad hoc version control to one of cyber resilience and centralized control. It provides:

- Automated, Git-based version control so every change is tracked and documented.

- Centralized, vendor-agnostic access to manage all code (Siemens, Rockwell, Schneider, Beckhoff, etc.) in one place.

- Rapid recovery plans that can reduce Mean Time to Recovery (MTTR) from days to minutes.

Understanding this history—of pairing people, process, and technology to accelerate production with quality—is the first step. But what are the real-world costs of ignoring this evolution?

Next in our series, we’ll dive into the staggering financial impact of downtime and why your C-Suite and plant floor likely have a dangerously different view of the problem.